- Home

- Products

- News

- Case

-

Factory Show

- German Dieffenbacher paving system

- German Dieffenbacher Continuous Flat Press Machine

- German AnThon Saw

- German Dieffenbacher Air Dryer

- Thermal energy center

- Canadian Kadant long veneer slicer

- German Dieffenbacher Maier Strand Flaker

- German Dieffenbacher OSB Blender

- German GreCon Supporting EWS Quality Monitoring System

- Swiss Baumer ColourBrain RawBoard 4.0

- Swiss Steinemann Sanding Machine

- Italian IMAL-PAL Super Screen

- German AnThon Saw

- chip bin

- Contact Us

- About Us

What Is OSB and How Is It Made?

2025-10-31 21:24

What Is OSB and How Is It Made?

Whether you are an experienced builder or just getting started in the construction industry, chances are you’ve used OSB boards in one of your projects. This engineered wood product is durable, cost-effective, and reliable — making it a top choice for sheathing, roofing, and flooring applications. But what exactly is OSB, and how is oriented strand board made? In this guide, HSosb walks you through what is an OSB and the detailed process behind its production.

What Is OSB?

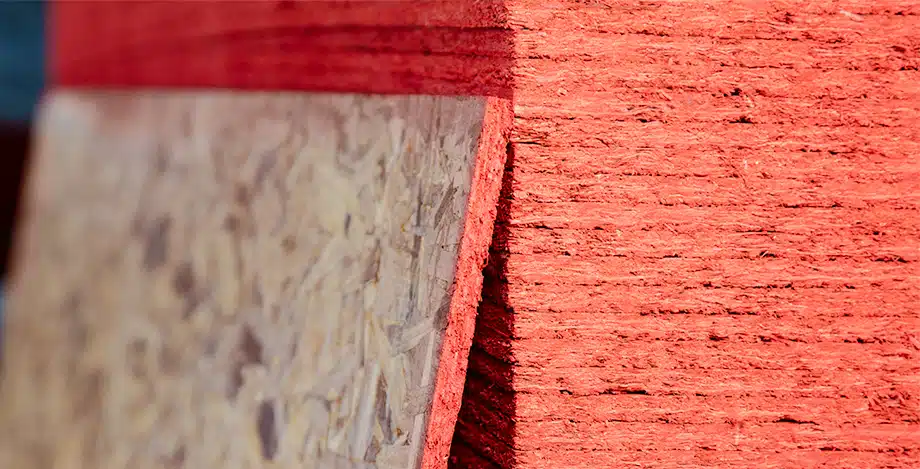

If you’ve ever stopped and wondered, “What is OSB?” here’s your answer. Oriented strand board (also known as oriented strandboard) is an engineered wood panel composed of compressed layers of wood strands arranged in specific orientations. Each layer is bonded with waterproof resin and wax, resulting in panels that are strong, moisture-resistant, and dimensionally stable.

During production, logs that might otherwise go unused are transformed into valuable construction materials. These wood strands are layered crosswise, pressed, and cured to create OSB boards that resist warping and splitting. They are widely used in both structural and non-structural applications — from roof decking and wall sheathing to subflooring and packaging solutions.

How It’s Made

Now that you understand what OSB is, let’s dive into the manufacturing process — a carefully engineered system designed to produce consistency and strength. If you’ve ever wondered how is OSB made or more specifically how is oriented strand board made, the following steps break down the process in detail:

Stacking & Aging

The process begins when trucks deliver logs to the mill. Using heavy-duty gantry cranes, the logs are unloaded and stacked into organized zones where they “age” for about two weeks. This conditioning step helps balance moisture and prepare the wood for further processing.

Separation & Drying

Once conditioned, the logs are sent through debarking drums to remove bark, then through a stranding machine that cuts them into thin, rectangular strands — around 2 inches by 6 inches by 0.03 inches. These strands are then conveyed to rotating drum dryers heated with high temperature air to remove moisture.

After drying, the strands are sorted by size. Smaller ones form the board’s core, while larger ones are saved for the outer faces. Each group of strands is stored in separate bins until ready for blending.

Applying the Finishing Touches

During blending, wax and adhesive resin are sprayed onto the strands to enhance durability and moisture resistance. On a forming line, strands are layered in a cross-oriented pattern—short strands inside, longer ones on the faces—creating a precise mat. These mats are cut into panels and pressed at temperatures up to 415°F, curing the resin and fusing the layers into solid boards.

After pressing, the panels are trimmed, sanded, sealed, and painted to achieve consistent quality before being stacked for shipment. This careful process explains exactly how is OSB board made with durability and performance in mind.

Choose HSosb OSB for Quality You Can Rely On

We hope this overview has answered your question about what is an OSB and offered new insight into how this strong, versatile material is produced. HSosb delivers superior oriented strand board designed for enduring performance in every build — from residential housing to large-scale commercial projects.

We hope this has answered the question of “What is OSB?” and provided insight into the OSB manufacturing process. The next time you see OSB featuring the HSosb logo, you’ll know exactly how those panels were made, from start to finish. If you have any questions about OSB or any of our other products, call +86-0714-6487189 or contact us online. Build better with HSosb.

Get the latest price? We'll respond as soon as possible(within 12 hours)