- Home

- Products

- News

- Case

-

Factory Show

- German Dieffenbacher paving system

- German Dieffenbacher Continuous Flat Press Machine

- German AnThon Saw

- German Dieffenbacher Air Dryer

- Thermal energy center

- Canadian Kadant long veneer slicer

- German Dieffenbacher Maier Strand Flaker

- German Dieffenbacher OSB Blender

- German GreCon Supporting EWS Quality Monitoring System

- Swiss Baumer ColourBrain RawBoard 4.0

- Swiss Steinemann Sanding Machine

- Italian IMAL-PAL Super Screen

- German AnThon Saw

- chip bin

- Contact Us

- About Us

Paving is a key factor affecting the quality of oriented structural board

Exploration Series 4/Paving is a key factor affecting the quality of oriented structural board

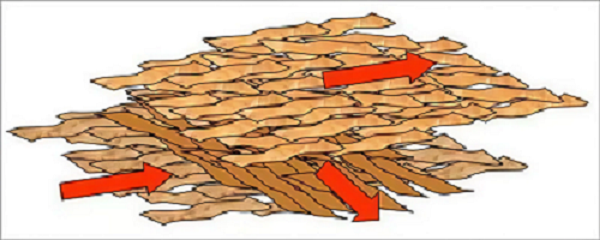

Paving is an important link that cannot be ignored in the production process of OSB/LSB. In the production process, the directional paving of narrow and long wood chips is a very important process. It requires paving the glued wood chips into uniform, quantitative, and directional slabs to ensure that the density and thickness are equal after hot pressing, and the strength is distributed in a certain proportion in the vertical and horizontal directions.

The particle shape of oriented structural board is different from that of ordinary particle board. It requires thin, narrow and long particles. The paving thickness will also affect the product quality. If the raw material is too thick during paving, the density of the pressed oriented strand board will be too high, and the internal stress will be large. After being placed for a period of time, it is easy to deform. Therefore, correct paving is of great significance for the production of oriented structural board with high strength, small expansion coefficient, light material and good surface quality.

The paving machine is the most important equipment that affects the performance of oriented structural boards. Ordinary paving machines generally have three oriented paving heads, the core layer is paved horizontally, and the surface layer is paved vertically. The main indicator for measuring the effect of oriented paving is the directional angle. The smaller the directional angle, the better the directional effect and the better the performance of the oriented structural board.

Hubei Huasheng has invested heavily in introducing the world's top German Deffenbach paving production line, which adopts five-layer oriented paving. Five metering silos automatically and evenly control the amount of shavings discharged. The shavings are paved with high precision through five paving heads. The upper and lower fine shavings are evenly paved as the surface of fine materials. The two layers of long large shavings in the middle are arranged vertically, and the core layer shavings are arranged horizontally. This comprehensive staggered structure makes the oriented structural board have extremely high dimensional stability and static bending strength. The board surface and board edge have strong nail holding force. At the same time, the texture structure of the wood is reorganized, and the influence of the internal stress of the wood on the processing is completely eliminated, so it has good processing performance.

The five-layer directional paving of Germany's Dieffenbacher paving production line enables various mechanical performance indicators of OSB/FOSB, improves static bending strength and elastic modulus, reduces the density of finished boards, reduces the use of raw materials, reduces the use of glue, and can input larger-sized shavings, directionally process shavings, and comb shavings so that the shavings can achieve the functions required by the definition of super strength.

Get the latest price? We'll respond as soon as possible(within 12 hours)